Industrial glucose (cultured industrial glucose), also known as whole sugar powder. White blocky solid with a sweet taste. Solid matter ≥ 80%, DE value ≥ 95, the product is widely used in industries such as sewage treatment, pharmaceuticals, chemicals, food, microbial fermentation, etc

Product basic information:

CAS number: 50-99-7

EINECS number: 200-075-1

Molecular formula: C6H12O6

Molecular weight: 180.1559

Density: 1.581g/cm3

Melting point: 146 ℃

Boiling point: 527.1 ° C at 760 mmHg

Flash point: 286.7 ° C

Water solubility: Solve

Steam pressure: 2.59E-13mmHg at 25 ° C

Specific rotation 52.75 º C (c=10, H2O, NH4OH 25 º C)

Refractive index 53 ° (C=10, H2O)

Appearance: Colorless crystal

Product features:

1. Industrial glucose solid products are pure white, white powder, and highly soluble in water.

2. Fast hydrolysis rate and weak hydration. The formed alum flowers are dense and settle quickly.

3. It is less affected by changes in water temperature and can meet the requirement of generating shear forces during the flow process.

4. It can effectively remove aluminum ions from the source water and residual free aluminum ions in the water after aluminum salt coagulation.

5. Low dosage, good treatment effect, and 10-20% cost savings compared to other coagulants.

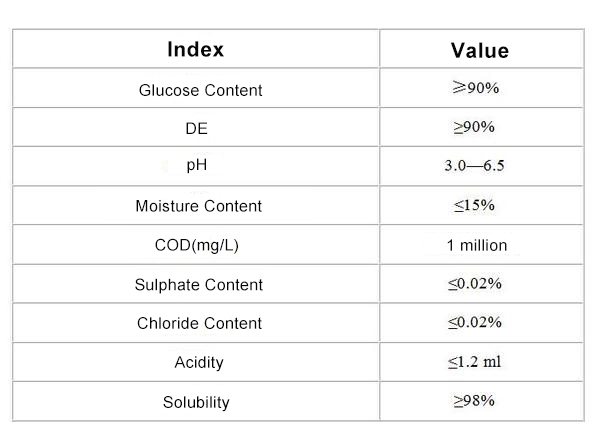

Product Parameter:

Product application:

1. Used in the field of medicine to regulate the acid-base balance in the human body and restore normal nerve function. Based on the same purpose, it is used as a food additive;

2. Used as a water quality stabilizer, its advantages are manifested in:

① It has a significant coordination effect and is suitable for various formulas such as molybdenum, silicon, phosphorus, tungsten, nitrite, etc. Due to the coordination effect, the corrosion inhibition effect is greatly improved;

② Unlike typical corrosion inhibitors, the corrosion inhibition rate increases with increasing temperature;

③ The anti scaling ability technology requires strong chelating ability for calcium, magnesium, and iron salts, especially excellent chelating effect for Fe3+;

④ As a corrosion and scale inhibitor for circulating cooling water, it is incomparable to other corrosion and scale inhibitors currently used, and can achieve the effect of eliminating pollution;

3. Used in the food industry, it can be used as a food additive because it can effectively prevent the occurrence of low sodium syndrome. Sodium gluconate and potassium gluconate have excellent taste thresholds. Sodium gluconate is non irritating, has no bitter taste, and has a salt flavor similar to table salt. Its threshold is much higher than other organic acid salts, which is 5 times that of table salt (inorganic salt), 2.6 times that of sodium malate, and 16.3 times that of sodium lactate. Sodium gluconate and potassium gluconate are used in food processing to adjust pH, improve food taste, and replace table salt to produce healthy low salt or salt free (sodium chloride free) foods. They play a significant role in promoting human health and enriching people's lives.

During the debugging period of sewage treatment, glucose and other substances are added to the processing industry to provide a carbon source, which is to better cultivate bacteria and improve the biodegradability of sewage. If the COD and BOD in the operating system are insufficient to supply the growth and reproduction of bacterial strains, additional addition is required to prevent sludge aging and reduced biological activity.

5. It can be directly used in the food and pharmaceutical industries, as a reducing agent in the printing and dyeing leather industry, and glucose is commonly used as a reducing agent in the mirror industry and silver plating process of hot water bottles. In industry, a large amount of glucose is used as raw material to synthesize vitamin C (ascorbic acid)

Product usage instructions:

1. According to the different conditions of the raw water, a small test can be conducted before use to determine the optimal dosage.

2. For production purposes, the ratio of solid to water is about 1/5. First, mix and dissolve the mixture, then dilute with water to a solution with a content of 2-3%.

Tel:

Email:1245771552@qq.com

Add:Zhanjie Industrial Park, Gongyi City, Henan Province, China