Corrosion and scale inhibitors are mainly composite corrosion and scale inhibitors composed of various organic phosphonic acids, polycarboxylic acids, sulfonic acid salt copolymers, copper corrosion inhibitors, special interfacial active agents, etc. They use the protective film formed by organic phosphonic acid salts on the metal surface to inhibit corrosion, and also have good chelating dispersion and lattice distortion effects on calcium carbonate, calcium sulfate, calcium phosphate, etc. in water. According to the principle of reasonable proportion, it fully utilizes its synergistic effect and has the characteristics of high corrosion inhibition rate, high temperature resistance, strong scale inhibition ability, and not easy to decompose.

Product Category:

Inorganic scale and corrosion inhibitors, such as polyphosphates, silicates, etc., prevent mineral precipitation in water through chelation.

Organic scale and corrosion inhibitors: including organic phosphonic acids and their derivatives (such as ATMP, HEDP, etc.), phosphonic carboxylic acids (such as AMPS, EDTMP, etc.), polycarboxylates, and other organic compounds with specific structures.

Product application areas:

Suitable for various water quality operating circulating water system environments, such as power plants, cement plants, printing and dyeing plants, paper mills, petrochemical plants, steel mills, circulating water, central air conditioning, injection molding equipment, cooling towers, closed and high-temperature cooling towers, evaporative condensers, heat exchange systems, etc.

Product features:

1. Effectively control the scaling of carbonates, silicates, and sulfates.

The appropriate pH value for the incoming water is 5-9.

3. Organic polymers can adjust the pH value and have the effect of efficiently controlling alkalinity.

4. It also has a descaling effect, and long-term use can remove scaling.

5. According to the water quality of the system, the general addition amount is 50-300ppm.

6. The corrosion inhibitor component is an imported high-efficiency substance, and the coverage rate increases proportionally with temperature rise.

7. Applicable to all circulating water systems.

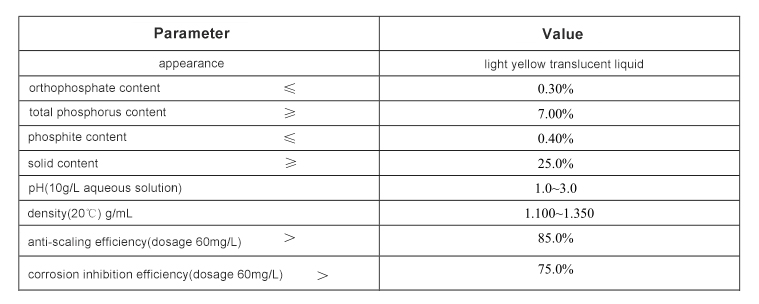

Product parameters:

Product usage instructions:

Direct addition: Add the corrosion and scale inhibitor directly into water or the system to be treated, and it will take effect after stirring evenly. This method is suitable for small-scale or temporary processing and is easy to operate.

Dispersed injection: Mix corrosion and scale inhibitors with water in a certain proportion, and disperse and inject them into the system under high-speed stirring or magnetic stirring. This method is more uniform than direct addition and can effectively prevent problems caused by excessive or insufficient dosage.

Static surface coating method: Dissolve corrosion and scale inhibitors in water and apply them to the inner walls of equipment and pipeline surfaces to form a protective film. This method is suitable for governing small caliber, complex systems, and long-term inactive systems.

Circulating injection method: Corrosion and scale inhibitors are mixed with water in a circulating device and injected into the system to be treated in a certain proportion through equipment such as a quantitative pump or automatic control system. This method is suitable for large-scale or long-term treatment, ensuring accurate dosage and stable effectiveness.

matters needing attention:

1. The furnace processing is easy to operate and master, but the operators must be responsible and conduct regular inspections and laboratory tests in order to achieve the expected results.

2. Before treating the water in the furnace, it is advisable to remove the scale as much as possible to prevent a large amount of old scale from falling off and blocking the pipeline. After the furnace is shut down, it should be flushed once and attention should be paid to changes in water level.

3. It is not classified as dangerous goods, non explosive, and non flammable.

4. It should be stored in a dry and ventilated place to prevent rain and sun exposure.

Tel:

Email:1245771552@qq.com

Add:Zhanjie Industrial Park, Gongyi City, Henan Province, China